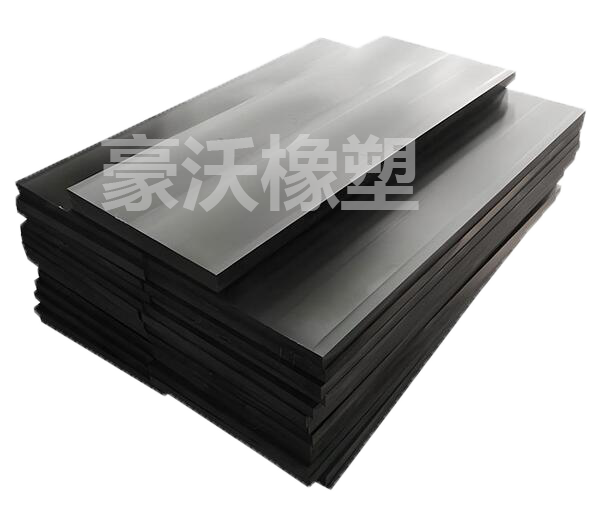

| 材質 | 超高分子量聚乙烯 | 產品類別 | 工程塑料 |

|---|---|---|---|

| 功能 | 耐磨抗腐蝕 | 規格 | 定制 |

| 抗壓強度 | 26Mpa≥ | 適用范圍 | 運輸、包裝、倉儲的重要器材 |

超高分子量聚乙烯板PP/PE板接來圖定制

超高分子量聚乙烯刮板綜合了如下優異性能:高耐磨性,高抗沖性,表面不粘性以及自潤滑性。并且,即使低溫條件下它亦能保持卓越的機械性能。高分子耐磨襯板是一種具有極高粘度的聚合物,為粉末形狀,其典型粒徑范圍為100一200微米。由于粘度很高,它通常不能用普通的熱塑性塑料成型方法來加工,而是用模壓或柱塞擠出工藝,在高壓下把超高分子量聚乙烯粒子熔融并燒結為坯材或型材,必要的話,再進行后續機加工。因為高分子耐磨襯板的耐磨性、耐化學性和好的摩擦性,其主要應用領域包括大批量材料搬運、食品和飲料加工機械、化工、采礦及礦物加工設備、娛樂設施、運輸,以及整形外科移植物。

高分子聚乙烯板的使用年限:高分子聚乙烯板的使用年限一般在8到10年之間它的耐磨系數極高,應用能力強是鋼鐵的10倍,高分子量等級具有極好的抗沖擊性,在常溫甚至在-40F低溫度下均如此。各種等級HDPE的獨有特性是四種基本變量的適當結合:密度、分子量分子量分布和添加劑。不同的催化劑被用于生產定制特殊性能聚合物。這些變量相結合生產出不同用途的HDPE品級:在性能上達到佳的平衡。具有良好的化學穩定性,可以抵抗大部份酸、堿、有機溶液,電氣絕緣性好。

UHMWPE board pp/pe board connection drawing

customization

UHMWPE scraper combines the following excellent properties:

high wear resistance, high impact resistance, surface non viscosity

and self lubrication. Moreover, it can maintain excellent

mechanical properties even under low temperature conditions.

Polymer wear-resistant liner is a kind of polymer with high

viscosity, which is in the shape of powder, and its typical

particle size range is 100-200 microns. Due to its high viscosity,

it is usually not processed by ordinary thermoplastic molding

methods, but by molding or plunger extrusion process, melting and

sintering UHMWPE particles into billets or profiles under high

pressure, and then subsequent machining if necessary. Because of

the wear resistance, chemical resistance and good friction of

polymer wear-resistant lining, its main applications include mass

material handling, food and beverage processing machinery, chemical

industry, mining and mineral processing equipment, entertainment

facilities, transportation, and plastic surgery grafts.

Service life of high molecular weight polyethylene sheet: the service life of high molecular weight polyethylene sheet is generally between 8 and 10 years. Its wear resistance coefficient is very high, and its application ability is 10 times that of steel. The high molecular weight grade has excellent impact resistance, even at room temperature and -40f low temperature. The unique characteristics of various grades of HDPE are the appropriate combination of four basic variables: density, molecular weight, molecular weight distribution and additives. Different catalysts are used to produce customized polymers with special properties. These variables combine to produce HDPE grades for different purposes: achieving the best balance in performance. It has good chemical stability, can resist most acid, alkali and organic solutions, and has good electrical insulation.

Tel:

Tel:

Tel:

Tel: